Trovaci a MECSPE 2026

29

C68

Livello di innovazione:

Vantaggi del prodotto:

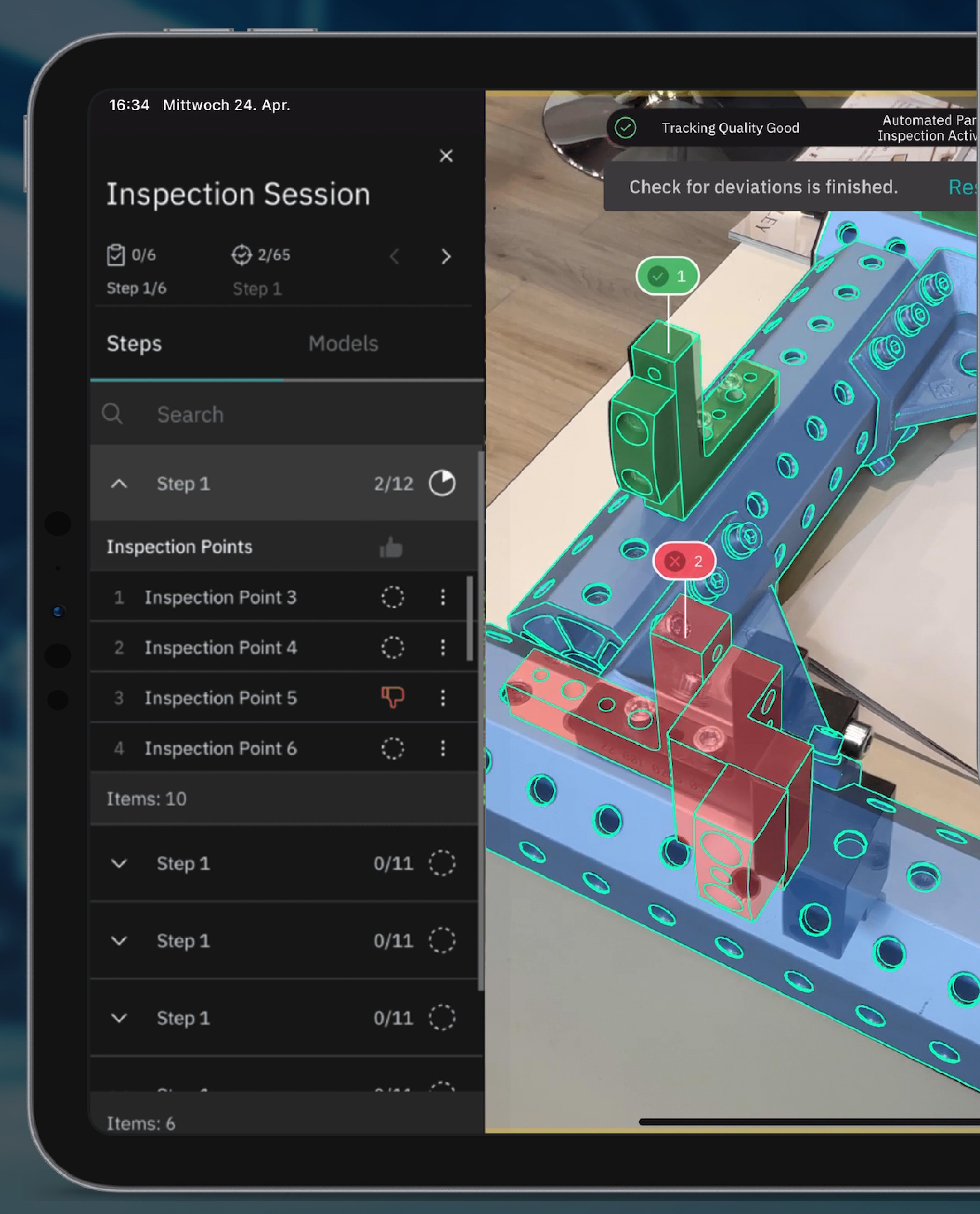

Twyn enables fast, intuitive, and reliable visual quality inspections directly on the production floor. By combining augmented reality with digital twins, it allows real-time verification of geometry, completeness, and correct assembly—without complex setups. This reduces inspection time and effort, detects deviations early, and ensures consistently high quality standards while increasing overall efficiency.

Settori di applicazione:

Twyn is used across manufacturing industries where visual quality and assembly accuracy are critical. Typical application sectors include automotive and mobility, aerospace, mechanical and plant engineering, and industrial manufacturing. Twyn supports quality inspection, assembly verification, and production validation directly on the shop floor, wherever complex parts and high quality standards are required.

Twyn is Visometry’s mobile AR platform for visual quality inspection. By overlaying digital twins directly onto physical parts, Twyn enables fast, intuitive, and on-site quality checks. Manufacturers can instantly verify geometry, completeness, and correct assembly in real time, reducing inspection effort while ensuring consistently high quality standards.